The long hole plug advantage in poor ground conditions

CONTEXT:

A recent survey was conducted on 89mm diameter production holes at Kirkland Lake Gold’s Fosterville Gold Mine in Victoria, Australia, to assess the hole diameter and ground conditions.

RESULTS:

Hole Diameter: All 89mm diameter production holes surveyed were between 80-90mm diameter. This was consistent with drilling 89mm diameter holes.

GROUND CONDITIONS:

Varying degrees of deformation of the holes due to stress damage was observed resulting in holes ‘crushing, spalling or dog earing’.

THE LONG HOLE PLUG ADVANTAGE

The Slotted Tube component of The Long Hole Plug anchors the unit in the hole by exerting a radial force on the sidewall of the hole and thus confining the rock mass around The Long Hole Plug in a similar way to that of a friction anchor. The value of this design feature is shown in the stress damaged holes observed during this borehole survey.

In the event that a Long Hole Plug is installed in a hole which later deteriorates in the same manner as observed The Long Hole Plug is able to maintain its integrity by confining the rock mass around the Slotted Tube component and thus keeping the unit firmly in place as shown in figure 2 (on page 2).

The crushing nature of the stresses exerted on the production holes further acts to lock The Long Hole Plug in place and hence enable The Long Hole Plug to perform appropriately.

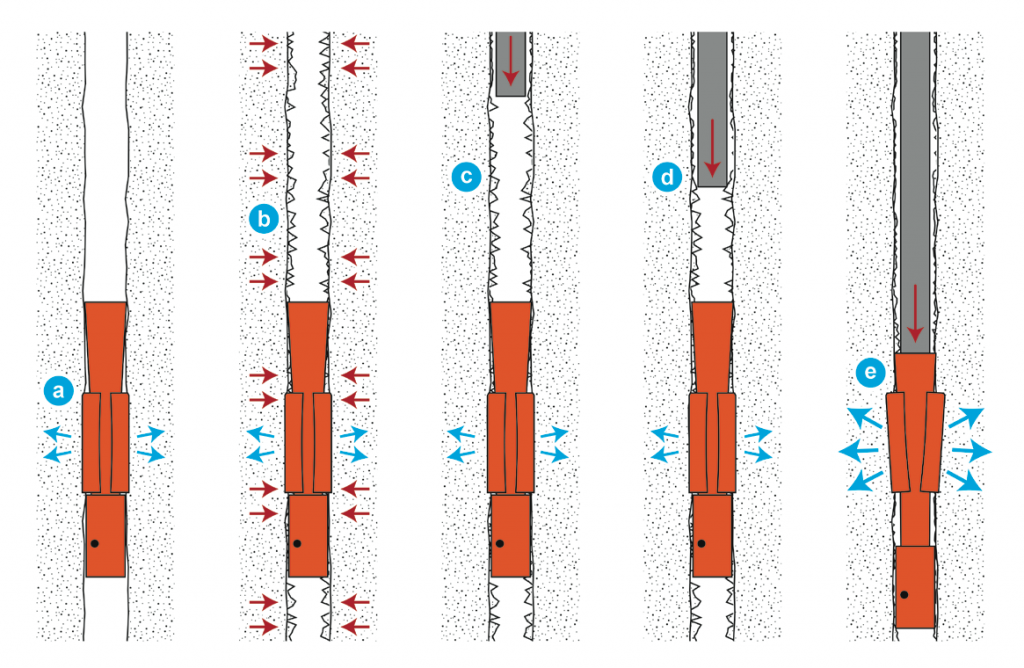

a: The Long Hole Plug installed in a freshly drilled production hole with the Slotted Tube exerting a radial force on the side wall of the hole

b: The stresses exerted on the rock mass causing the production hole to ‘crush, spall or dog ear’ with The Long Hole Plugs Slotted Tube still exerting a radial force on the side wall of the production hole,

c & d: The drill rods starting to fall down towards The Long Hole Plug with the Slotted Tube still exerting

a radial force on the side wall of the production hole,

e: The drill rods making contact with The Long Hole Plug resulting in the Tapered Section being driven into the Slotted Tube resulting in an increase in the radial force being exerted on the side wall of the production hole.

Kirkland Lake Gold’s Fosterville Gold Mine – Case Study

Kirkland Lake Gold’s Fosterville Gold Mine – Case Study